Foamboard posters are one of our most popular products.

Here is how we make them.

The first step is image review.

We take the customer's image, check its size, and compare that to the size of the print.

If there are any concerns about print quality, we send the image to review.

In image review, a specialist will use image super resolution to enhance the image and make sure it prints well.

Here's an example of how good super resolution can work:

(We also have a free super resolution tool that you can try here).

Once the image is ready to print, we will lay it out and save it in Tiff format.

Once we have enough images, we will fill out a print sheet.

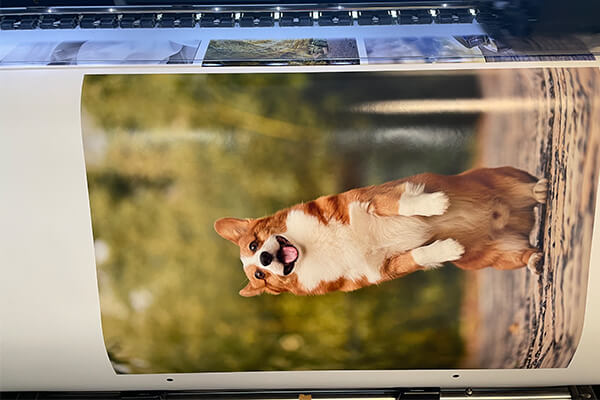

A print sheet look like this:

Now that we have the print sheet ready, we will send it to the printer.

It comes out of the printer and gets wound into roll.

Then we use a laminating machine to apply the printed roll to a foamboard sheet.

Once the print has been applied to the sheet, we take it to the cutting table.

It looks like this:

The table has a camera system that scans the black dots on the edges of the print.

It used those scans to make cutting instructions.

We hit play, and the foamboards are cut from the big sheet.

Like this:

Then we cover them with foam wrap.

Then they are bubble wrapped and boxed.

And the foamboard print is ready to ship.

That is how we make foamboard prints.

You can order foamboard prints here.